Press Release

Trucks

are shifting into the future with revolutionary GearMaster® technology

SALT LAKE CITY, UT.,

June 20, 2002 — GearMaster International announced today the completion

of its development program for the GearMaster II, the latest generation of

the

company’s flagship product for the trucking industry. The

GearMaster is an instrument that allows semi-truck drivers to virtually

see inside their transmission while they are driving. It

is a visual method of displaying what goes on in a transmission and what

the relationship is between engine speed and vehicle speed.

By referring to the GearMaster’s interactive graphic display, a driver can instantly and intuitively observe which gears are available to him and how fast the engine needs to be going to shift into any of those gears. The GearMaster can be used with virtually any truck on the road and can accommodate up to 20 gears.

The GearMaster lets drivers virtually see inside their transmission while

they are driving

HOW THE GEARMASTER WORKS

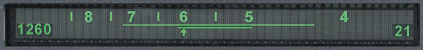

The image above shows how the GearMaster display might look in a typical driving configuration. The vertical lines between fifth and sixth, sixth and seventh, seventh and eighth and ninth represent the split gears available on some transmissions.

Tachometer Arrow

The arrow on the bottom dynamically scrolls left and right relative to the speed of the engine. It is essentially a tachometer.

Range Line

The line in

the middle represents the calibrated operating range of the engine, say 700 to

1800 RPM for a typical large diesel truck. This line can optionally be set to

represent the maximum torque range also.

The Gear Numbers

The numbers

at the top scroll left and right relative to the speed of the vehicle, each

number being calibrated to its respective gear. The numbers move to the

right with increasing vehicle speed and

move to the left with decreasing vehicle speed.

Visual

Synchronization of Available Gears

The GearMaster

presents a visual synchronization of available gears on its graphic display. The

gear numbers displayed anywhere directly above the range line are available to

the driver. Any gear numbers that are not displayed above the range line should

not be attempted. Whenever a number is aligned directly above the arrow, the

engine and vehicle speed are perfectly synchronized for that gear.

Digital Tachometer

and Speedometer

The GearMaster can be optionally configured to display engine speed (RPM) and vehicle speed (MPH), as shown below on the right.

|

|

| RPM Vehicle Speed |

For a better understanding of how the GearMaster would appear under various

driving conditions, refer to the images below.

|

|

| Engine off. Vehicle not moving |

|

| Engine at idle (700 RPM). Vehicle not moving |

|

| Engine at high RPM (1800 RPM). Vehicle is not moving |

|

|

First gear is engaged. Engine nearing upper end of range. Vehicle is moving slowly. Second gear available |

|

|

Clutch is disengaged (or transmission in neutral). Engine near idle. Vehicle is coasting. 3rd and 4th Gears are available. Note that 1st gear has disappeared off the right end of the screen. |

|

Vehicle being driven in 7th gear.

—or—

Transmission is in neutral but is ready to be shifted into 7th gear

(with or without use of the clutch). 6th gear and 8th gear are also available. |

In the above example, if a driver were approaching the crest of a downgrade and wanted to be in fifth gear, one glance at the display would immediately indicate that he/she could not engage fifth gear without over-speeding the engine, grinding the gears, or both. The best course of action would be to engage sixth gear, apply heavy braking until fifth gear comes into range and then shift into fifth gear.

. . . A great safety feature of the GearMaster !I

THE GEARMASTER II

The GearMaster II incorporates several significant improvements over the original instrument. These improvements include the following:

-

The auxiliary electronic box has been eliminated, thus reducing the complexity of installation and the space required.

-

Both hardware and software have been modified to enable the GearMaster to receive engine and vehicle speed information through the ECM data port. This has reduced installation and calibration time to less than 15 minutes and has enabled the GearMaster to be installed on virtually every heavy truck made in the world today.

-

The new unit retains the ability to receive speed and RPM information from the senders on which the older system was based. This means that the GearMaster II can be directly retrofitted to earlier installations as well as to trucks without an ECM or data port.

-

At the users option, a digital indication of speed and/or RPM can be displayed while the GearMaster is in operation.

-

The digital speed display can be shown in miles per hour (mph) or kilometers per hour (kph).

-

The display brightness can be toggled between day and night settings as on the former unit. The new unit, however, allows the user to set each brightness level.

Company president, Kent H. Price, said that the development was completed on time and within budget. "I am also very pleased that the development included production savings which will allow us to offer the improved unit to our customers with no increase in cost," he said.

A NEW INNOVATION

The GearMaster is a relatively new technology in the heavy

trucking industry and can benefit every fleet operator, owner-operator and

the over two million drivers on the road today. The benefits are numerous. The

GearMaster can:

·

Reduce driver turnover

·

Eliminate transmission intimidation for new

drivers

·

Reduce the cost of training new drivers

·

Reduce fuel usage

·

Eliminate the need and the cost of adding

AutoShift

·

Reduce wear & tear on transmissions, clutches

and engines

·

Help drivers stay in the optimal engine operating

range

·

Improve safety and reduce accidents

·

Keep trucks on the cutting-edge of technology

NECESSITY IS THE MOTHER OF INVENTION

RJ

Young is a heavy truck driver and driving trainer who has had decades of

experience on the road. In training new drivers, he observed the real

struggle most of them experience in gaining the ability to shift gears

efficiently. Young knew that there must be a more effective way for

drivers to shift gears. He teamed up with Kent H. Price, an engineer

and business owner with skills in manufacturing, electronics and technical

programming. Together, they designed and developed the instrument

known today as the GearMaster.

In explaining how the GearMaster works, the inventors say that the primary purpose of the GearMaster is to fulfill a driver's need to know which gears are available to him, and how fast the engine needs to be operating in order to successfully shift into any gear.

They built into the GearMaster a visual method of displaying the functions of the transmission, and of showing the relationship between the engine speed and vehicle speed.

With only a quick glance at the GearMaster's interactive display, the truck driver will be instantly and intuitively aware of which gears can be engaged at the vehicle's current speed and will know what to do with his engine to smoothly shift into any of those gears.

The GearMaster is conveniently installed on the dashboard in

front of the driver and easily plugs into the standard six-pin or nine-pin

ECM data port found on virtually all newer trucks. Newer trucks

can become operational with the GearMaster in less than fifteen minutes,

according to Mr. Price.

AMERICAN MADE

Made in America, the GearMaster is entirely solid state and is produced to exacting specifications to enable the unit to resist heat, vibration and other adverse environmental conditions.

As if advanced functionality and effectiveness of the GearMaster were not enough, company president Kent H. Price points out that the GearMaster can also solve some of the most serious problems existing in the trucking industry, today.

For example, the highly simplified and well-displayed GearMaster is expected to significantly change the way new drivers are trained. Non-productive training time will be reduced, and driver retention will be enhanced.

By keeping truck fleets on the cutting edge of technology, driver turnover can be reduced and other efficiencies can be realized. These include fuel savings and improved safety.

Although the GearMaster was not initially designed to operate a vehicle without using the clutch, Young says that an average driver can run through the entire range of gears (even skipping gears, if desired) with no grinding or jerks, and having to use the clutch only when coming to a complete stop.

Young continues, "Whether using the clutch or not, the GearMaster enables the driver to synchronize the engine to the optimum gear and minimize wear and damage on both the clutch and transmission."

Because of the costs associated with a typical driver turnover rate of 100 percent or more per year, fleet owners are becoming increasingly aware of and sensitive to any technical advance, which can improve driver retention.

According to a recent study by the Upper Great Lakes Transportation Institute, drivers polled listed why they choose to work for their current employers:

· Location of Company

· More time at home/better schedule

· Higher pay than from fleet's competitors; and

· Fleet operates better equipment

According to Frank Palmeri, Director of Strategic Marketing

of the Meritor Corporation, better equipment

can be a key factor as to why a fleet either retains an experienced driver

or has to recruit one from another carrier. "Component suppliers, who

stay in touch with the market, understand this well, and they factor it

in, as they develop their next generation of products and services,"

Palmeri said.

STANDARD

EQUIPMENT?

Many Heavy Trucking Industry observers agree that the GearMaster is on the cusp of a truck technology that will dramatically improve driver training and provide all drivers with instant information and feedback so critical to efficiency and safety on the road. Some have even expressed the opinion that the GearMaster may one day become standard equipment in all heavy-duty trucks.

"Dead

in the water..."

A

recent experience is typical of many drivers who don’t have the

GearMaster in their trucks. "We were under heavy load driving into

Manhattan across the George Washington Bridge. My trainee lost his

gear and spent the next several seconds grinding from this gear to that. I

wanted to lean over and shift for him but we were in a cab-over and it was too far to reach. Finally, with horns honking,

people yelling and several drivers indicating with hand gestures that they

thought we were "number one," we had no choice but to come to a

complete stop and start over in first gear. He was simply dead in the

water. I don't ever want to go through that again...."

A Matter of Life or Death?

Sometimes shifting can in fact be a matter of life or

death. Take for example, the time the new fireman in Michigan was driving

an older tanker truck on the way to a fire. He couldn't find his gear

and was trying so hard that the gearshift lever actually broke off in his

hand. Needless to say, he did not make it to the fire on time. When

the GearMaster was subsequently demonstrated to the department, that

driver and others were able to smoothly shift from gear to gear and an

immediate sale resulted.

More of what people are saying:

"Man, I wish I had had that thing when I was

learning to drive! It would have saved a lot of grinding"

- B. T., Green Bay, Wisconsin

"Every trainer ought to have one of these!"

- R.C., Salt Lake City, Utah

"The GearMaster will pay for itself several times

over in one year. Just think of the cost of one transmission rebuild

or one runaway accident that could have been prevented." - T.W.,

San Louis Obispo, California

"It really removes a lot of the stress from

driving. I can concentrate much better on the road." - T.D.,

Detroit, Michigan

"I've been driving for years and often shift

without a clutch by listening to the engine. Now I can have the radio

up and still synchronize my shifting. And it's more precise than I

can get from the sound." - R.G., Grand Rapids, Michigan

New drivers are simply less intimidated by the big

rigs when they have a GearMaster installed. It gives them an intuitive

visual view of what gears are available to them at any moment in time.

"It's like being able to look inside the transmission while you are

driving", one driver said.

GearMaster offers a free video that demonstrates how the

system operates. A telephone call to 1-866-GEARSAV (1-866-432-7728)

is all that it takes to schedule an actual demonstration of the GearMaster

at your location. GearMaster is available now directly from GearMaster for

$1,495.00.

GearMaster International, a division of Johnson Manufacturing

Company located near Salt Lake City, Utah, makes the GearMaster. Johnson

was incorporated in Michigan in 1949 and, prior to the introduction of the

GearMaster, was a manufacturer of small high-precision parts primarily for

aerospace instruments and jet engines. GearMaster International

specializes in innovative technical solutions for the heavy equipment and

trucking industry. The company can be reached at 801-554-0015 or (toll free)

1-866-432-7728 (1-866-GEARSAV). The company’s web site is located

at www.gearmaster.com.